Model: MG-140CS

Cooling capacity: 40 TR, 142 KW 50hp

Refrigerant: R407c / r134a / R22

Compressor power: 46 KW

Water flow: 24 m3/h

Power supply:3PH~220V/380/415V~50HZ/60HZ

Dimension(L*W*H):2300*1400*2050mm

Weight:1900 KG

Certification: CE, UL, ISO9001

Application:Industrial Cooling Solutions

Compressor type:Semi-closed Screw Type

Evaporator style:Shell and Tube Type

Payment Term:50% in advance and 50% before delivery

Pump:Centrifugal Pump

24/7 Online Support

86-17686681005

Description

Description

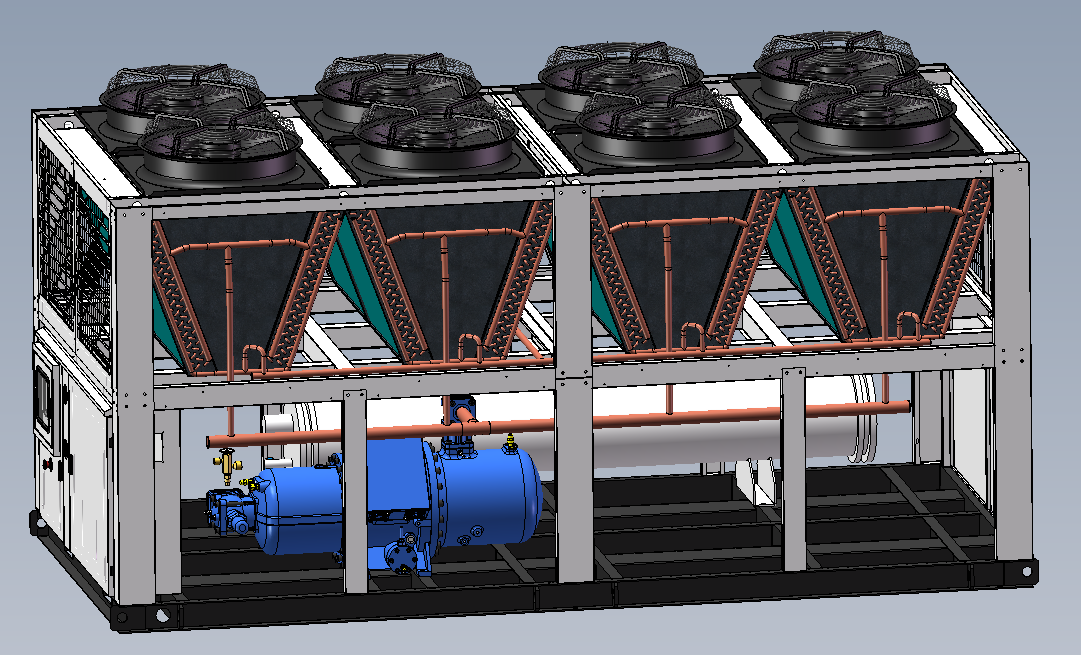

MGREENBELT Series industrial chiller is mainly applied in Plastic & Rubber industry, it can accurately control the molding temperature and shorten the molding circle, increase the product quality and improve the production efficiency. They are widely used in Metal working, Mechanical & Engineering, Chemical & Pharmaceutical, Food & Beverage, Laser, Electronics industry, Textile, Electroplate, Semi-conductor testing, Water jet, Vacuum coating, Construction and Military.

1. The screw type chiller cooling capacity: 80 KW~600KW, for plastic industry chiller suggest the +7 deg C ~35 deg C normal outlet series.

2. Voltage: 220/380V/415V/440V/460V-3PH-50HZ/60HZ.

3. Refrigerant: R22, R407.R134, R404a, R507 optional.

4. Chilled water temperature: -15 to 35 DegC. Also as per customer’s demand to adjust.

5. Shell and tube type evaporator and Aluminium fins type condenser.

Note: If you need air cooled chiller price, our products could meet your requirements. And Customized units are welcome like 415V/3Ph/50Hz, 220V/3Ph/60Hz, 440V/3Ph/60Hz etc.

1.Emerson expansion valve.

2.Self-processing components: Condenser, Evaporator, SS storage tank and Cabinet self-processing.

3.Refrigerant: R22 charged, CFC free type R407C, R410A, R134A for option.

4.Energy efficient solutions: our specialists are aware of the rising cost of energy and the pressure to reduce energy consumption, and offer many energy saving products that favor life time costs including variable speed pump & fan packages and energy efficient refrigeration products.

5. Multi-protection devices ensure the chiller unit running safety.

-Compressor inner protection,

-over current protection,

-high/low pressure protection,

-over temperature protection,

-High discharge temperature alarm

-flow rate protection,

-phase sequence/phase missing protection,

-low level coolant protection,

-anti freezing protection,

-exhaust overheat protection

-high/low pressure protection

-over temperature protection

-High discharge temperature alarm

Parameter

Parameter

|

Air Cooled Screw Chiller Normally Temperature Series( Single System) |

|||||||||||

|

Model |

MG-80C |

MG-110C |

MG-140C |

MG-155C |

MG-200C |

MG-260C |

MG-300C |

MG-420C |

MG-520C |

MG-600C |

|

|

Cooling Capacity |

USRT |

22.2 |

31.0 |

40.4 |

43.5 |

57.7 |

72.2 |

86.7 |

120.0 |

148.7 |

170.6 |

|

Kcal/h |

67080 |

93740 |

122120 |

131580 |

174580 |

218440 |

262300 |

362920 |

449780 |

516000 |

|

|

KW |

78 |

109 |

142 |

153 |

203 |

254 |

305 |

422 |

523 |

600 |

|

|

Power |

3PH-380V-50Hz |

||||||||||

|

Refrigerant |

Type |

R22/R407C |

|||||||||

|

Control |

Thermostatic expansion valve |

||||||||||

|

Comperssor |

Type |

semi-closed screw type |

|||||||||

|

kw Power |

28 |

37 |

46 |

51 |

66 |

79 |

94 |

124 |

160 |

182 |

|

|

Start |

Y-△ |

||||||||||

|

Capacity |

33%-66%-100% |

25%-50%-75%-100% |

|||||||||

|

Evaporator |

Type |

High efficiency copper tube shell and tube type |

|||||||||

|

m³/h Flow |

13 |

19 |

24 |

26 |

35 |

44 |

52 |

72 |

90 |

103 |

|

|

Inlet/outlet |

DN65 |

DN65 |

DN80 |

DN80 |

DN80 |

DN80 |

DN80 |

DN100 |

DN125 |

DN150 |

|

|

Condenser |

Type |

High efficiency hydrophilic aluminum foll finned type |

|||||||||

|

m³/h Flow |

30000 |

40000 |

50000 |

60000 |

80000 |

100000 |

120000 |

160000 |

200000 |

240000 |

|

|

Protection System |

Compressor overheat protection, high/low pressure protection,phase missing/sequence protection, flow rate protection, anti-frozen protection. |

||||||||||

|

Dimension |

L(mm) |

2700 |

2450 |

2300 |

3300 |

4050 |

4050 |

4960 |

4680 |

5680 |

6680 |

|

W(mm) |

1120 |

1400 |

1860 |

1950 |

1950 |

1950 |

1950 |

2250 |

2250 |

2250 |

|

|

H(mm) |

1800 |

2050 |

1800 |

2000 |

2000 |

2150 |

2150 |

2460 |

2460 |

2460 |

|

|

wight |

kg |

1800 |

1900 |

2300 |

2480 |

3000 |

3100 |

3600 |

5000 |

6000 |

6800 |

Details

Details

|

No

|

Item

|

Data

|

|

1

|

Model

|

MG-140CS

|

|

2

|

Cooling Capacity

|

142 Kw at +7 deg C outlet |

|

3

|

Input Power

|

46 KW

|

|

4

|

Pump Input Power

|

3 KW

|

|

5

|

Power Supply

|

380V/3PH/50HZ or as customer need

|

|

6

|

Refrigerant

|

R404a, R407c, R507 , R22

|

|

7

|

Condenser

|

Ripple Aluminum Fins around Cooper Pipe

|

|

8

|

Evaporator

|

Shell And Tube Type / Plate Exchanger

|

|

9

|

Tank Volume

|

External water tank

|

|

10

|

Dimension L×W×H

|

2300*1860*1800 mm

|

1. Micro programming Control System.Industrial PLC centralized control combined with compressor capacity control system,built-in full intelligent monitoring and protection including thermal motor temperature monitoring, phase sequence monitonng, manua reset lock-out, oil temperature sensor.

2. V shape aluminum fin type condenser, assuring adequate heat exchanging area within smaller unit size.High effcient evaporator with internal thread copper tube.Large air volume axial fan with metal blades.

3. Using world famous brand semi-hermetic screw compressor- Bitzer from Germany and Handbell from Taiwan, the screw compressor features high EER value, low noise, stable operation.

Each screw compressor with 4 steps of energy control 25%-50%-75%-100% to make sure the whole screw chiller is stable and guarantee high refrigeration performance.

There are also 2 or 3 screw compressors for optional depends on the required refrigeration capacity.

5. China Top quality water pumps, in order to convenient for customer use and installation, we can make the SKID-MOUNTED for the one pump use, one pump stand by, include the soft connection and valve.

Structural

Structural

Professional Industrial Refrigeration Equipment Solution Provider.