Minus 10C Chemical Process Chiller Industrial Air Cooled Process Chiller

Process temperature: -10 deg C for chemical process, or if customer need lower is workable.

Chilled water flow: from 20 m3/h to 200 m3/h

Dimension: 4050*1950*2000mm

Weight: 3000kg

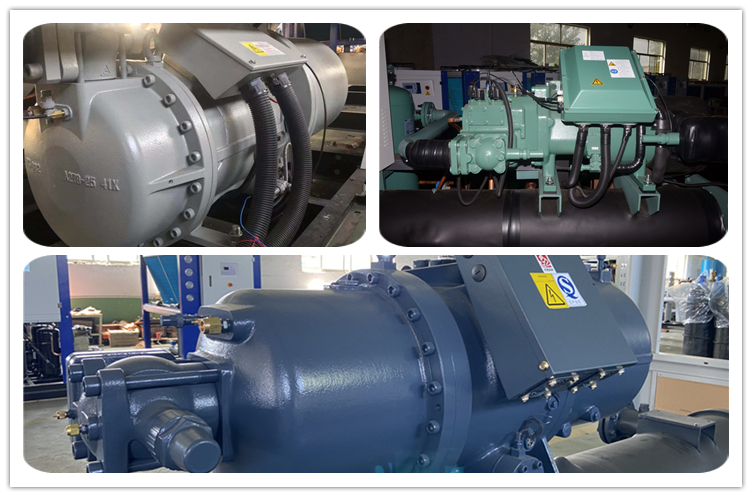

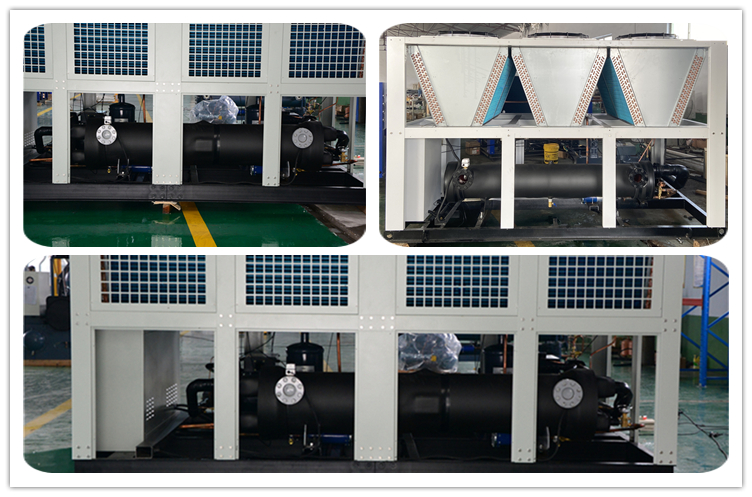

High quality branded screw compressor Energy efficiency air-cooled type condenser

Temperature control from -15℃to 35℃

Dry shell and tube evaporator

No need to install a cooling tower

Easy installation&Operation and maintenance

24/7 Online Support

86-17686681005

Description

Description

Air cooled water chiller, chemical process chiller, low temperature chiller, glycol water chiller is widely used for Chemical, pharmaceutical, biodiesel, methane purification, methanol purification, fermentation, beverage, food, dairy and etc process.

1. The screw type chiller cooling capacity: 40 KW~600KW, the lowest temperature suggest -15 deg C, if lower than -15 deg C, we suggest the water cooled type chiller, that will be higher efficient for customer.

2. Voltage: 220/380V/415V/440V/460V-3PH-50HZ/60HZ.

3. Refrigerant: R22, R407.R134, R404a, R507 optional.

4. Chilled water temperature: -15 to 35 DegC. Also as per customer’s demand to adjust.

5. Shell and tube type evaporator and Aluminium fins type condenser.

Note: If you need air cooled chiller price, our products could meet your requirements. And Customized units are welcome like 415V/3Ph/50Hz, 220V/3Ph/60Hz, 440V/3Ph/60Hz etc.

* Compact Design;

* Simple Operation;

* Safety Protection;

* Easy Movement With Caster;

* Chilled Water Pump;

*Stainless Steel Water Tank;

*Rotor Type Brand Compressor.

*Remote control(Line switch) is optional.

|

No

|

Item

|

Data

|

|

1

|

Model

|

MG-200CSL

|

|

2

|

Cooling Capacity

|

100 Kw at -10 deg C outlet ; 125kw at -5 deg C |

|

3

|

Input Power

|

66.8 KW

|

|

4

|

Pump Input Power

|

5.5 KW

|

|

5

|

Power Supply

|

380V/3PH/50HZ or as customer need

|

|

6

|

Refrigerant

|

R404a, R407c, R507 , R22

|

|

7

|

Condenser

|

Ripple Aluminum Fins around Cooper Pipe

|

|

8

|

Evaporator

|

Shell And Tube Type / Plate Exchanger

|

|

9

|

Tank Volume

|

External water tank

|

|

10

|

Dimension L×W×H

|

4050*1950*2000 mm

|

Parameter

Parameter

|

Air Cooled Screw Chiller Normally Temperature Series( Single System) |

|||||||||||

|

Model |

MG-80C |

MG-110C |

MG-140C |

MG-155C |

MG-200C |

MG-260C |

MG-300C |

MG-420C |

MG-520C |

MG-600C |

|

|

Cooling Capacity |

USRT |

22.2 |

31.0 |

40.4 |

43.5 |

57.7 |

72.2 |

86.7 |

120.0 |

148.7 |

170.6 |

|

Kcal/h |

67080 |

93740 |

122120 |

131580 |

174580 |

218440 |

262300 |

362920 |

449780 |

516000 |

|

|

KW |

78 |

109 |

142 |

153 |

203 |

254 |

305 |

422 |

523 |

600 |

|

|

Power |

3PH-380V-50Hz |

||||||||||

|

Refrigerant |

Type |

R22/R407C |

|||||||||

|

Control |

Thermostatic expansion valve |

||||||||||

|

Comperssor |

Type |

semi-closed screw type |

|||||||||

|

kw Power |

28 |

37 |

46 |

51 |

66 |

79 |

94 |

124 |

160 |

182 |

|

|

Start |

Y-△ |

||||||||||

|

Capacity |

33%-66%-100% |

25%-50%-75%-100% |

|||||||||

|

Evaporator |

Type |

High efficiency copper tube shell and tube type |

|||||||||

|

m³/h Flow |

13 |

19 |

24 |

26 |

35 |

44 |

52 |

72 |

90 |

103 |

|

|

Inlet/outlet |

DN65 |

DN65 |

DN80 |

DN80 |

DN80 |

DN80 |

DN80 |

DN100 |

DN125 |

DN150 |

|

|

Condenser |

Type |

High efficiency hydrophilic aluminum foll finned type |

|||||||||

|

m³/h Flow |

30000 |

40000 |

50000 |

60000 |

80000 |

100000 |

120000 |

160000 |

200000 |

240000 |

|

|

Protection System |

Compressor overheat protection, high/low pressure protection,phase missing/sequence protection, flow rate protection, anti-frozen protection. |

||||||||||

|

Dimension |

L(mm) |

2700 |

2450 |

2300 |

3300 |

4050 |

4050 |

4960 |

4680 |

5680 |

6680 |

|

W(mm) |

1120 |

1400 |

1860 |

1950 |

1950 |

1950 |

1950 |

2250 |

2250 |

2250 |

|

|

H(mm) |

1800 |

2050 |

1800 |

2000 |

2000 |

2150 |

2150 |

2460 |

2460 |

2460 |

|

|

wight |

kg |

1800 |

1900 |

2300 |

2480 |

3000 |

3100 |

3600 |

5000 |

6000 |

6800 |

Details

Details

1. Micro programming Control System.Industrial PLC centralized control combined with compressor capacity control system,built-in full intelligent monitoring and protection including thermal motor temperature monitoring, phase sequence monitonng, manua reset lock-out, oil temperature sensor.

2. V shape aluminum fin type condenser, assuring adequate heat exchanging area within smaller unit size.High effcient evaporator with internal thread copper tube.Large air volume axial fan with metal blades.

3. Using world famous brand semi-hermetic screw compressor- Bitzer from Germany and Handbell from Taiwan, the screw compressor features high EER value, low noise, stable operation.

Each screw compressor with 4 steps of energy control 25%-50%-75%-100% to make sure the whole screw chiller is stable and guarantee high refrigeration performance.

There are also 2 or 3 screw compressors for optional depends on the required refrigeration capacity.

4.Highly efficient closed-loop shell and tube type heat exchanger as the evaporator

5. China Top quality water pumps, in order to convenient for customer use and installation, we can make the SKID-MOUNTED for the one pump use, one pump stand by, include the soft connection and valve.

Welcome check our air cooled chemical process chiller details

Industrial chemical chiller project reference

Structural

Structural

Professional Industrial Refrigeration Equipment Solution Provider.