24/7 Online Support

86-17686681005

Description

Description

30KW 40KW 50KW Industrial Beer Cooling Glycol Water Chiller

What Can A Glycol Chiller Be Used For?

Glycol chillers are most used for chemical processing, pharmaceutical formulation, food and beverage processing etc.

Breweries

In breweries, using a glycol chiller allows producers to lower the temperature of the product dramatically over a short period of time, depending on the production needs.

For cooling in brewing, there are several processes in which it is important to lower or maintain the temperature – such as cooling the beer sharply after fermentation, or maintaining a steady temperature during fermentation (which generates heat), or cooling the wort after the initial boiling process.

Wineries

Winery chillers are used in the fermentation process of winemaking to control the temperature during fermentation. The temperature of the glycol solution varies depending on the type of wine being made and each winemaker’s preference, but most winery chillers operate in the 2 Deg C to 10 Deg C range (7 Deg C to 15 Deg C for wine containers).

Dairy Product

A properly designed dairy glycol chiller can cool the milk very rapidly to help keep milk temperatures (and bacteria growth) under control as it is transferred from the milking parlor to his insulated tank.

30KW 40KW 50KW Industrial Beer Cooling Glycol Water Chiller Features

Compressor: This air-cooled water chiller can automatically alternate operation according to load changes, balancing the operating load of the compressor, greatly extending the service life of the chiller unit. Good performance and low noise.

Evaporator: The evaporator adopts a reinforced copper tube with inner and outer threads, the copper tube has a good cooling effect. The evaporator barrel is insulated with a 26mm thick PE insulation board. No condensation and less cold loss.

Condenser: The condenser is equipped with efficient cross-seam fins and female threaded copper tubes for high heat exchange efficiency and good stability.

Protection Device: Temperature control switch, high and low-pressure switch, overload protector, compressor overheat protector, frequent start protector, and abnormal indicator to protect the water chiller system.

Computer Control System:has developed a highly intelligent PLC, which can do remote monitoring and control. Simple operation, low failure rate, high safety factor, easy installation.

Box Material: The box plate of the fully closed chiller unit is precision processed by a CNC punching machine, using electrostatic powder baking paint, beautiful appearance, and good sound insulation.

Parameter

Parameter

30KW 40KW 50KW Industrial Beer Cooling Glycol Water Chiller Parameters

| Model | MG-3C | MG-5C | MG-6C | MG-8C | MG-10CD | MG-12CD | MG-15CD | MG-20CD | MG-25CD | MG-30CT | MG-40CF | MG-50CF | ||

| Cooling capacity | 0℃ | kw | 6.8 | 10.5 | 12.2 | 16.2 | 22.8 | 24.8 | 33.4 | 44.2 | 50.5 | 66.9 | 87.7 | 110.6 |

| -5℃ | kw | 5.7 | 8.9 | 10.3 | 13.8 | 19.3 | 21 | 28.4 | 37.6 | 43 | 56.8 | 74.5 | 94 | |

| Power | kw | 3.45 | 5.45 | 6.31 | 8.22 | 10.54 | 12.33 | 15.84 | 20.51 | 23.52 | 31.81 | 40.18 | 47.92 | |

| Power input | 3PH-380V-50HZ | |||||||||||||

| Refrigerant | Type | R22/R407C | ||||||||||||

| Control | Thermostatic expansion valve | |||||||||||||

|

Compressor |

Type | Hermetic scroll type | ||||||||||||

| Power | kw | 2.95 | 4.2 | 5.4 | 7.4 | 4.2*2 | 5.4*2 | 6*2 | 9.05*2 | 10.6*2 | 9.05*3 | 9.05*4 | 10.6*4 | |

| Evaporator | Type | SS Tank with coil or Shell and tube | ||||||||||||

|

m³/h Flow |

0℃ | 1.29 | 1.99 | 2.31 | 3.07 | 4.32 | 4.70 | 6.33 | 8.37 | 9.57 | 12.68 | 16.62 | 20.96 | |

| -5℃ | 1.17 | 1.83 | 2.12 | 2.84 | 3.97 | 4.32 | 5.84 | 7.73 | 8.85 | 11.68 | 15.33 | 19.34 | ||

| Capacity | L | 50 | 70 | 70 | 120 | 200 | 200 | 270 | 350 | 350 | 450 | 580 | 580 | |

| Inlet/Outlet | DN25 | DN25 | DN32 | DN32 | DN32 | DN32 | DN40 | DN40 | DN40 | DN65 | DN65 | DN80 | ||

| Condenser | Type | High efficiency hydrophilic aluminum foll finned type | ||||||||||||

| kw Power | 0.24 | 0.52 | 0.52 | 0.24*2 | 0.46*2 | 0.46*2 | 0.55*2 | 0.78*2 | 1.7*2 | 0.78*3 | 1.5*2 | 1.7*4 | ||

| pump | Type | Centrigual water pump | ||||||||||||

| Power | kw | 0.37 | 0.37 | 0.37 | 0.55 | 0.55 | 0.55 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | |

| lift | m | 24 | 25 | 24 | 20 | 20 | 20 | 20 | 20 | 20 | 21 | 20 | 19 | |

| Protection System | Compressor overheat protection, high/low pressure protection,phase missing/sequence protection, flow rate protection, anti-frozen protection. | |||||||||||||

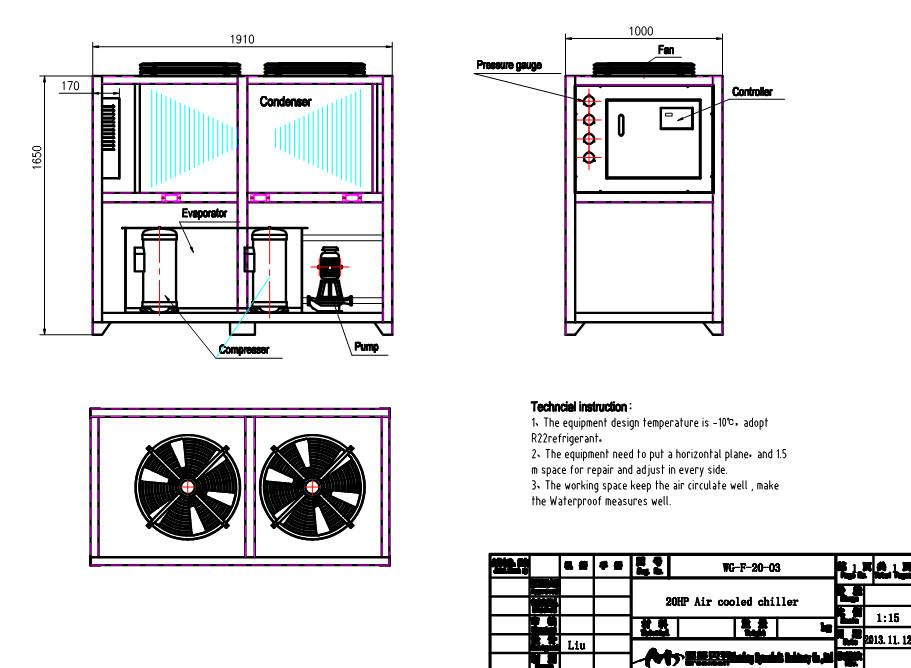

| Dimension | L | mm | 1120 | 1220 | 1220 | 1430 | 1610 | 1610 | 1870 | 2120 | 2120 | 2700 | 2450 | 2300 |

| W | mm | 570 | 600 | 690 | 780 | 820 | 820 | 900 | 1000 | 1000 | 1120 | 1400 | 1860 | |

| H | mm | 1150 | 1200 | 1200 | 1450 | 1500 | 1500 | 1600 | 1720 | 1720 | 1800 | 2100 | 1800 | |

| Wight | kg | 150 | 200 | 230 | 310 | 450 | 500 | 750 | 850 | 900 | 1150 | 1350 | 1600 | |

Details

Details

Structural

Structural

Professional Industrial Refrigeration Equipment Solution Provider.